Sewer & Pipe Lining Rehabilitation

At Onsite India we have extensive hands on experience in successfully dealing with ALL TYPES of pipes rehabilitation, with our core specialty being SEWER & PIPE LINING SERVICES using state-of-the-art trenchless No Dig Technology.

OnSite’s approach to repair and remediation is always to seek solutions which minimise the need for excavation. The Company utilises a number of technologies and is constantly researching the market place for new and innovative techniques. This approach enables greater flexibility and offers the asset owners more potential solutions for any given complexity of problem encountered.

OUR EXPERTISE: Trenchless Rehabilitation With CIPP

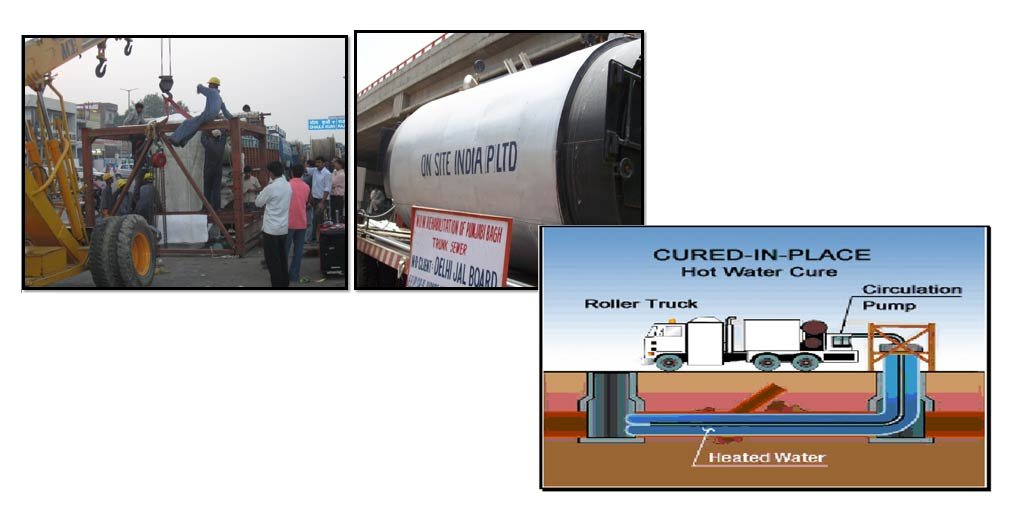

Trenchless Rehabilitation intially involved rehabilitating the sewers and pipes using GRP Lining. But with constant advances in the technology, trenchless rehab at OnSite is now achieved through world class and effective CIPP Lining methodology.

- CIPP the world’s most popular method of pipe rehabilitation.

- Though recently introduced in India its history dates back to as far as 1972.

- This method is highly suitable for potable water mains and pressure pipes too.

- This is applicable to and has been successful for all shapes and diameters.

- An inversion in Delhi of 150 metres in a 1600 mm diameter pipe at a depth of 5+ metres took only 16 hours.

- Lining was done in a controlled temperature of 20°c which is ideal, while the atmospheric temperature outside was above 40°C.

- The guaranteed life of the liner is 50+ years.

Every liner shows

- Meterage reading

- Batch number

- Order number

A customer can identify

- Manufacturing date of the liner

- Installer of the liner

- The engineer responsible for the contract

Standards Followed:

- WRc (Water Research Council Manual)

- ASTM F1216,

- WIS 4-34-04 for CIPP

Other Positives:

- Increase or restore the integrity of the existing pipe system

- Relatively quick rate of renovation

- Variations in diameter of the carrier pipe can be accommodated

- Grouting between the lining and the carrier pipe is not required

- The systems are capable of negotiating bends in the carrier pipe

- Space constraints

- Time Constraints

- Long term cost effectiveness

- Quality control

- Minimal disruption

- Environmental benefits

- Quick rate of renovation

- CIPP allows for replacement of pipes without disturbing surface structures or other utilities.

- It produces a seamless, Joint less pipe lining with minimal reduction of the original pipe diameter and leaves no voids to be grouted after the liner is installed.

- The smooth interior of the liner reduces friction, which increases flow capacity.

- It has a guaranteed 50+ year life.

CIPP is the most versatile rehabilitation method that has widespread applicability in the field of pipeline renewal.

Sewer and storm water systems in cities worldwide suffer from insufficient capacity, construction failures and pipe deterioration.

The traditional response has been to remove and replace them.

Today, there are alternatives available which can rehabilitate the sewer line or utility access, at a lower cost with less inconvenience to the general public and significantly extending the service life of the installation.

Cured in Place Pipe (CIPP) rehabilitation is a technique for relining ‘full length’ pipes (manhole to manhole) insitu’. This results in a quick, simple and cost effective ‘no dig’ solution to costly pipe renewal with minimal disruption.

OnSite has extensive experience in delivering effective no-dig rehabilitation solutions on a range of foul, surface and process pipelines ina broad range of working environments including utility, industrial, transport and commercial. Utilising proven technology, OnSite provides no-dig solutions which match the needs of the user whilst solving the issues of any given working environment.

OUR SOLUTION: Involves the following steps:

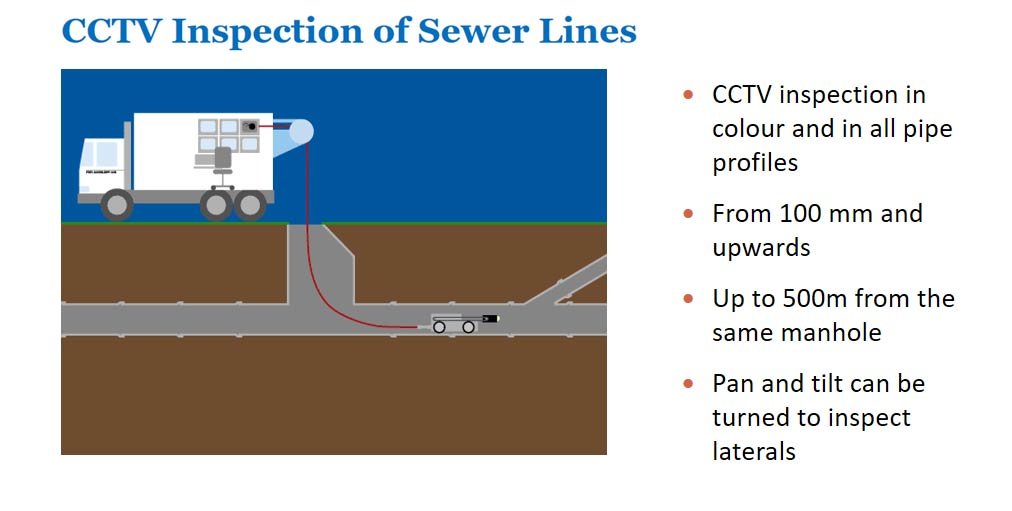

Asset Data Collection & Mapping the Entire Network

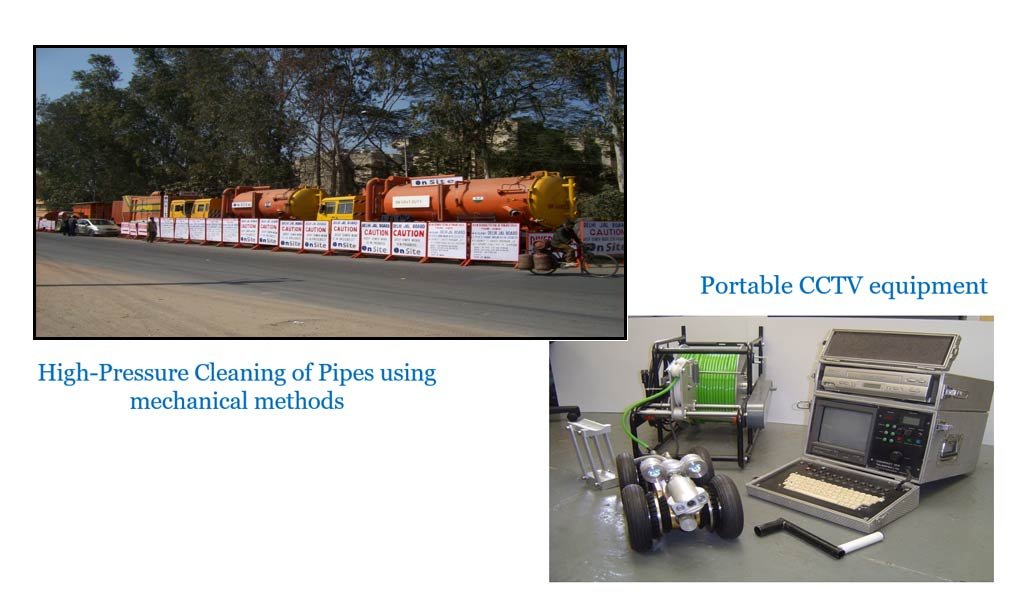

Cleaning & Survey